From Athletic Powerhouse to Strategic Restructuring

Under Armour‘s journey from a garage startup to a $5 billion athletic apparel giant is well-documented. However, the company’s recent struggles offer a sobering lesson in how supply chain vulnerabilities can amplify during periods of organizational decline and restructuring. As the Baltimore based company faces its most challenging period yet, the ripple effects through its supply chain operations provide valuable insights for supply chain professionals navigating similar turbulent waters.

The Perfect Storm: Multiple Crises Converge

Under Armour’s supply chain team found themselves at the epicenter of a multi-faceted crisis that began building momentum in the early 2020s. The company faced a confluence of challenges that would test even the most resilient supply chain operations.

COVID-19 and Geographic Concentration

The pandemic exposed Under Armour’s heavy reliance on Chinese manufacturing. When COVID-19 lockdowns hit China in 2022, the company was forced to strategically cancel orders as production facilities shuttered and capacity shortfalls became the norm. This geographic concentration, once viewed as a cost advantage, became a critical vulnerability that supply chain teams scrambled to address.

Inventory Nightmare

By 2023, Under Armour was drowning in excess inventory—a problem that had been building for years. The supply chain team faced the unenviable task of managing bloated stock levels while simultaneously trying to maintain service levels and forecast accuracy. The disconnect between demand planning and reality created a domino effect that rippled through every aspect of supply chain operations.

Technology Disruption

Adding salt to the wound, Under Armour’s 2017 ERP system implementation had created lasting disruptions in supply chain visibility and coordination. Years later, teams were still dealing with the aftereffects of data inconsistencies and process inefficiencies that made agile response to market changes nearly impossible.

The Human Cost: How Supply Chain Teams Suffered

Impossible Expectations

Supply chain professionals at Under Armour found themselves caught between conflicting mandates. They were expected to reduce costs while maintaining service levels, cut inventory while avoiding stockouts, and streamline operations while managing increasing complexity. These contradictory objectives created enormous stress on teams already stretched thin.

Resource Constraints

As financial pressure mounted, supply chain teams faced budget cuts that made their jobs exponentially harder. Travel restrictions limited face-to-face vendor relationships, technology upgrades were postponed, and training programs were slashed, while the team was expected to navigate unprecedented challenges.

The Layoff Reality

The restructuring announcements in 2024 brought the harsh reality home. Supply chain professionals, many who had dedicated years to building relationships with suppliers and optimizing processes, suddenly found themselves facing job insecurity. The institutional knowledge walking out the door with departing team members created additional operational risks that the remaining skeleton crew had to manage.

Vendor Relationship Strain

Perhaps most damaging was the erosion of supplier relationships. Late payments, order cancellations, and constant renegotiations strained partnerships that had taken years to build. Supply chain managers found themselves in the uncomfortable position of asking suppliers for favors while simultaneously cutting their business.

The Restructuring Reality Check

Under Armour’s 2024 restructuring plan represents a sobering acknowledgment of operational realities. The decision to exit the Rialto, California distribution facility and implement widespread layoffs signaled a fundamental shift in the company’s supply chain strategy. The $85 million restructuring cost demonstrates the expensive reality of unwinding complex supply chain operations.

The company’s focus on reducing SKUs by 25% represents a classic supply chain simplification strategy born from necessity rather than choice. When you can’t manage complexity effectively, the solution often becomes eliminating complexity entirely. This is a lesson many supply chain teams learn the hard way.

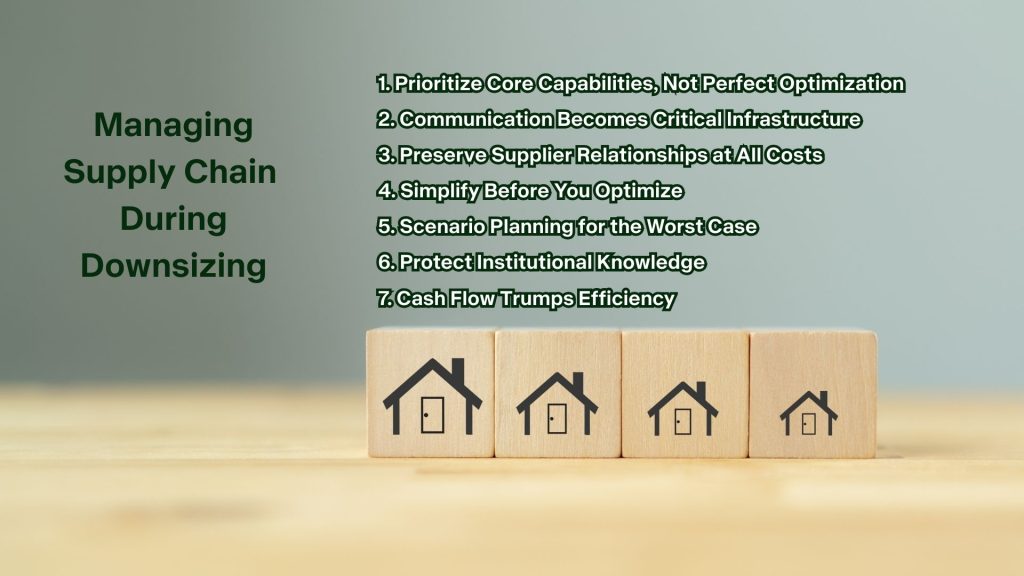

Key Learnings: Managing Supply Chain During Downsizing

1. Prioritize Core Capabilities, Not Perfect Optimization

When resources are limited, focus on maintaining essential supply chain functions rather than pursuing optimization initiatives. Ensure basic visibility, supplier payments, and customer service levels are protected before investing in advanced analytics or process improvements.

Practical Application:

- Maintain minimum viable inventory levels for core products

- Focus supplier development efforts on critical partners only

- Simplify KPIs to focus on cash flow and service level fundamentals

2. Communication Becomes Critical Infrastructure

During downsizing, communication gaps can be catastrophic. With fewer people handling more responsibilities, over-communication becomes essential.

Practical Application:

- Implement daily supplier communication protocols during crisis periods

- Create simple dashboards that provide visibility across reduced teams

- Establish clear escalation paths for when skeleton crews encounter issues

3. Preserve Supplier Relationships at All Costs

Suppliers often become the lifeline during difficult periods. Companies that maintain trust and transparency with suppliers during downsizing fare better in recovery periods.

Practical Application:

- Be transparent about payment timelines and company challenges

- Honor commitments even if it means making difficult trade-offs elsewhere

- Involve key suppliers in solution development rather than just problem notification

4. Simplify Before You Optimize

Complex supply chain networks require sophisticated management resources. When those resources are constrained, simplification becomes survival.

Practical Application:

- Reduce SKU complexity before cutting staff

- Consolidate suppliers to focus management attention

- Streamline processes to reduce coordination requirements

5. Scenario Planning for the Worst Case

Hope for the best, but plan for scenarios where things get worse before they get better. Supply chain teams need contingency plans that assume further resource constraints.

Practical Application:

- Develop supplier backup plans that don’t require extensive relationship development

- Create modular supply chain designs that can scale down gracefully

- Build flexibility into contracts that accommodates company volatility

6. Protect Institutional Knowledge

When layoffs are inevitable, capture and transfer critical supply chain knowledge before it walks out the door.

Practical Application:

- Document key supplier contact information and relationship history

- Create process documentation for critical but infrequent activities

- Cross-train remaining team members on essential functions

7. Cash Flow Trumps Efficiency

During survival mode, cash flow preservation often requires abandoning traditional supply chain efficiency metrics.

Practical Application:

- Extend payment terms where possible, even if it costs more

- Reduce safety stock to free up working capital, accepting higher risk

- Prioritize supplier partners who can provide favorable payment terms

The Path Forward: Lessons for Supply Chain Leaders

Under Armour’s supply chain struggles offer a masterclass in how interconnected challenges can overwhelm even experienced teams. The company’s experience demonstrates that supply chain resilience isn’t just about having backup suppliers or alternative shipping routes. It’s about building organizational capacity to manage through prolonged periods of constraint and uncertainty.

For supply chain professionals, Under Armour’s story serves as a reminder that operational excellence during good times must be balanced with the ability to maintain core functions during difficult periods. The companies that emerge strongest from downsizing are often those whose supply chain teams learn to do more with less while preserving the relationships and capabilities needed for eventual recovery.

The athletic apparel industry will continue to evolve, and Under Armour may yet write a comeback story. However, the supply chain lessons from their recent struggles will undoubtedly influence how the next generation of supply chain leaders approaches risk management, relationship building, and operational resilience in an increasingly volatile business environment.