The supply chain world is constantly evolving, and a new debate has emerged regarding two dominant SCOR (Supply Chain Operations Reference) models. On one side stands the traditional SCOR model (Plan, Source, Make, Deliver, Return), supported mainly by Gartner. On the other, the Association for Supply Chain Management (ASCM) has introduced the SCOR Digital Standard (SCOR DS), a modernized framework built for the digital era. Which one is superior? Who will come out on top? Let’s break it down.

Introduction to SCOR

The Supply Chain Operations Reference (SCOR) model has been a cornerstone in supply chain management since its inception in 1996. Developed by PRTM and AMR Research, and later managed by the Association for Supply Chain Management (ASCM), SCOR has undergone significant updates to keep pace with evolving supply chain dynamics. In 2022, ASCM introduced the SCOR Digital Standard (SCOR DS), marking a substantial overhaul of the original framework. This blog post delves into the differences between the old SCOR model and the new SCOR DS, highlighting key enhancements and implications for supply chain management.

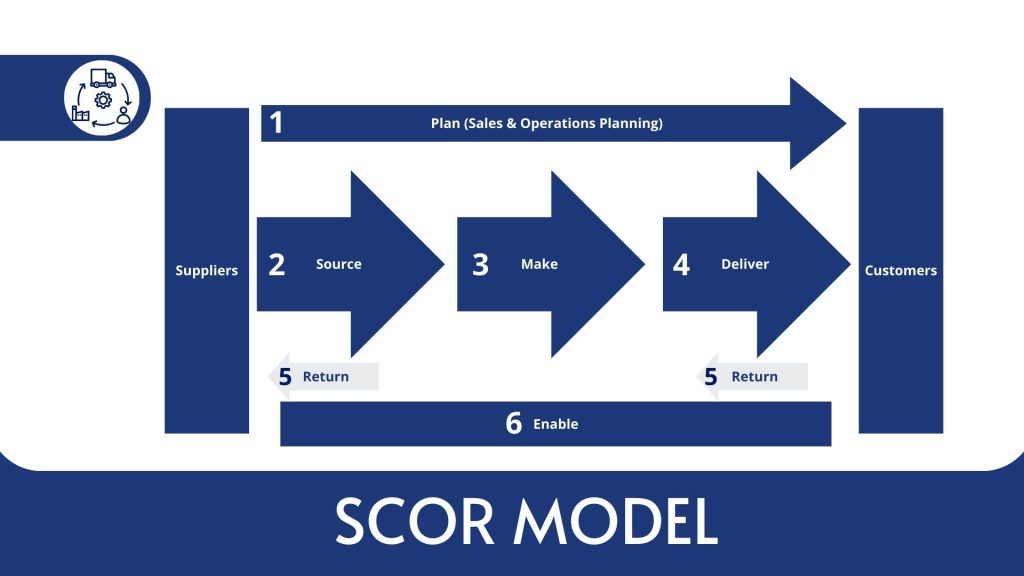

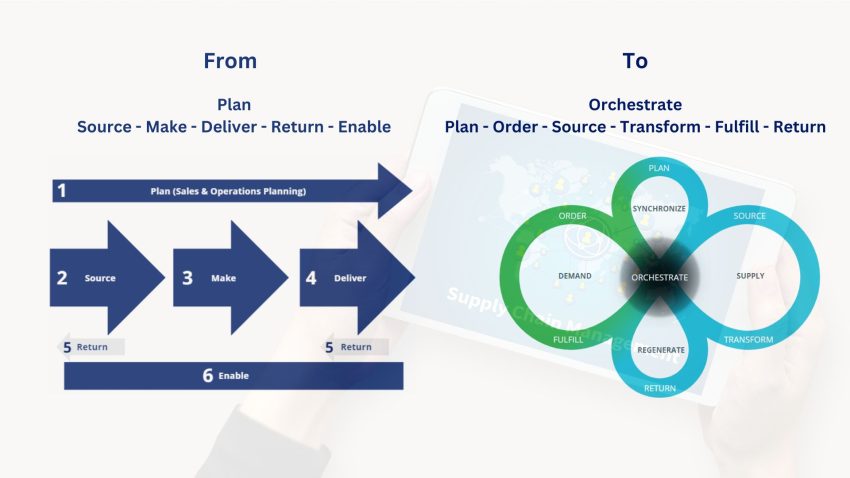

The SCOR model was designed to provide a standardized framework for analyzing, improving, and communicating supply chain processes. It originally consisted of five primary processes: Plan, Source, Make, Deliver, and later added Return and Enable. These processes were structured in a linear fashion, reflecting traditional supply chain operations.

Old SCOR Model

The original SCOR model followed a linear approach, where processes were sequential and distinct. Below core processes are included:

- Plan: Define and align supply chain strategy.

- Source: Procure goods and services.

- Make: Manufacture products.

- Deliver: Manage order fulfillment.

- Return: Handle returns and reverse logistics.

- Enable: Manage supply chain infrastructure and support processes.

New SCOR DS Model

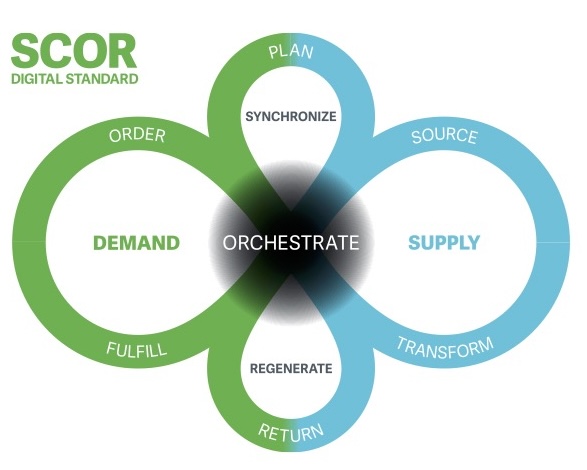

The Supply Chain Operations Reference Digital Standard (SCOR DS) is the latest iteration of the SCOR model, introduced by the Association for Supply Chain Management (ASCM) in September 2022. This comprehensive, open-access framework is designed to help organizations assess and enhance their supply chains, leading to improved business performance.

SCOR DS introduces seven core processes:

- Orchestrate: Focuses on integrating and enabling supply chain strategies, including business planning, human resources, technology, data analytics, compliance, risk mitigation, and sustainability initiatives.

- Plan: Involves developing roadmaps for operating the supply chain, determining requirements, and balancing resources across Order, Source, Transform, Fulfill, and Return processes.

- Order: Covers activities related to customer purchases, such as order entry, payment methods, pricing, and fulfillment status.

- Source: Addresses procurement activities, including ordering, scheduling, delivery, receipt, and transfer of products and services.

- Transform: Encompasses the creation of products through production, assembly, maintenance, repair, and overhaul.

- Fulfill: Pertains to executing customer orders, including scheduling delivery, picking, packing, shipping, installation, and invoicing.

- Return: Deals with the reverse flow of goods and services, focusing on diagnostics, entitlement evaluation, and reintegration into the supply chain.

The new SCOR Digital Standard (SCOR DS) builds on the foundation of the old SCOR model but incorporates advancements in technology, data analytics, and digital transformation. Here’s a breakdown of the key differences:

1. Digital-First Approach

- Old SCOR Model: Focused on traditional supply chain processes, with limited integration of digital tools and technologies.

- SCOR DS: Embraces a digital-first mindset, incorporating technologies like IoT, AI, blockchain, and advanced analytics to enable real-time decision-making and predictive insights.

2. Enhanced Agility and Resilience

- Old SCOR Model: Primarily designed for linear supply chains, with less emphasis on adaptability to disruptions.

- SCOR DS: Prioritizes agility and resilience, enabling organizations to respond quickly to market changes, disruptions, and customer demands.

3. Data-Driven Decision Making

- Old SCOR Model: Relied on historical data and manual analysis, limiting the ability to predict future trends.

- SCOR DS: Leverages big data and predictive analytics to provide actionable insights, improving forecasting accuracy and operational efficiency.

4. Customer-Centric Focus

- Old SCOR Model: Focused on internal processes and efficiency, with less emphasis on customer experience.

- SCOR DS: Places greater emphasis on customer-centricity, enabling organizations to deliver personalized experiences and meet evolving customer expectations.

5. Sustainability and Ethical Practices

- Old SCOR Model: Limited focus on sustainability and ethical considerations.

- SCOR DS: Integrates sustainability and ethical practices into the core framework, helping organizations reduce their environmental impact and meet regulatory requirements.

Key Benefits of the SCOR DS Model

- Improved supply chain visibility and transparency.

- Faster and more accurate decision-making through advanced analytics.

- Greater adaptability to market changes and disruptions.

- Enhanced customer satisfaction and loyalty.

- Stronger focus on sustainability and corporate social responsibility.

How to Transition from the Old SCOR Model to SCOR DS

- Assess Your Current State: Evaluate your existing supply chain processes and identify areas for improvement.

- Invest in Technology: Adopt digital tools and platforms that align with the SCOR DS framework.

- Train Your Team: Equip your workforce with the skills and knowledge needed to leverage the new model effectively.

- Monitor and Optimize: Continuously track performance metrics and refine your processes to maximize the benefits of SCOR DS.

Conclusion

The new SCOR DS model represents a significant leap forward in supply chain management, offering a more agile, data-driven, and customer-centric approach. By transitioning to SCOR DS, organizations can stay ahead of the competition, drive operational excellence, and achieve long-term success in an increasingly digital world.

Ready to take your supply chain to the next level? Explore the SCOR DS framework today and discover how it can transform your operations.

2 thoughts on “Exploring the Evolution of SCOR: A Comparison of the Old and New SCOR DS Models”